Feeding Systems

Flex-Flo Feed Delivery

AP’s Flex-Flo™ feed delivery system adapts to a variety of configurations and capacities to meet today’s demanding production requirements.

Durable PVC Tubing

Durable PVC Tubing

AP’s polyvinyl chloride (PVC) tubing is extruded in our own facility, to exacting standards and under our own quality control. Blended PVC allows us to formulate the optimum compound for UV stabilization, strength, and wear resistance.

Quality Auger

Quality Auger

AP augers are coiled in-house from high tensile steel for consistent quality and strength. AP uses wire which is flattened prior to hardening which provides better resistance to distortion and an all around stronger product.

Around The Bend

Around The Bend

For moving feed up in the air and around corners, AP Flex-Flo™ elbows are specially formed with increased wall thickness on the inside of the elbow for added strength and wear resistance.

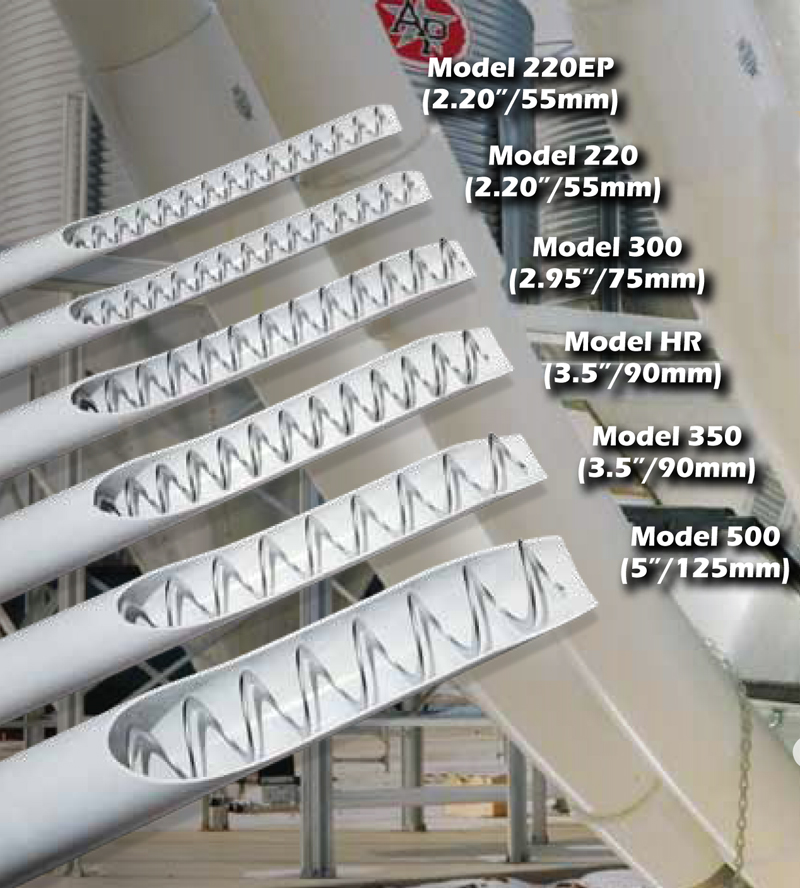

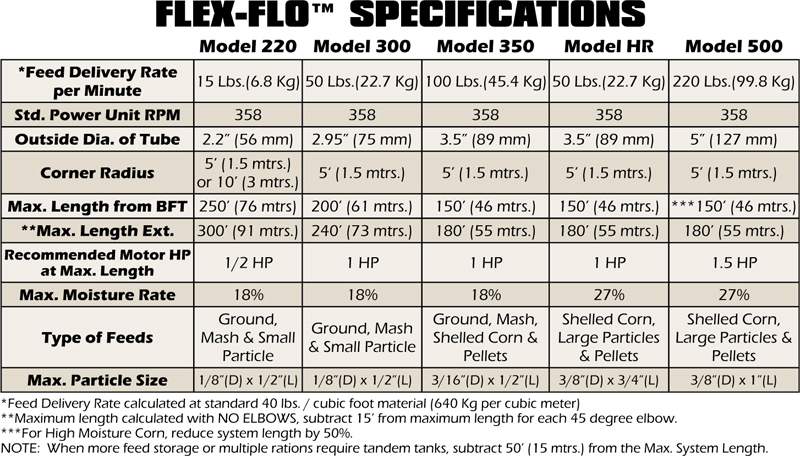

Flex-Flo Models

Both tubing and augers are available in a variety of models to fit your specific requirements. Whether its ground feed, mash, high moisture corn, shelled corn or pellets, AP has the combinations to handle it.

Quality Unloaders

Quality Unloaders

Unloaders are available for Model 220, 300, 350, HR and 500 Flex-Flo™ or 4” and 6” rigid auger systems. Most unloaders are available in single or double outlet models, as well as “through” models for use in tandem tank systems.

Unloaders feature heavy duty ball bearing anchor & bearing assemblies to increase service life and reduce maintenance. All unloaders have a slide gate above the auger to shut feed off and a side inspection door.

Plastic Boots

Plastic Boots

AP offers straight drop, 30°, and double boot models. All are chemically blended with specially formulated ultraviolet inhibitors and impact modifiers to enhance durability. AP’s clear boot model provides an easy visual of bin feed levels.

Control Units

Control Units

AP offers both drop tube and hopper level switches as automatic shut-off options. Both units are located at the last feeder in the line. Drop tube switches and hopper level controls are also available with an optional proximity style switch with time delay.

Precise Control

Precise Control

AP offers both drop tube and hopper level switches as automatic shut-off options. Both units are located at the last feeder in the line. Drop tube switches and hopper level controls are also available with an optional proximity style switch with time delay.

Power Units

Power Units

The Flex-Flo™ auger is driven by a 1/3 to 1-1/2 hp, totally enclosed, fan cooled motor at a standard 358 RPM (other speeds available for special applications). Whether direct or belt driven, the drive system includes an easily accessible maintenance port, a safety back up switch and visible light warning of back ups in the feed line, and automatic thermal shut-off switch.

Extension Units

Extension Units

For applications requiring distances over the maximum auger length for that size auger, extension hoppers are available to extend the overall length of the Flex-Flo system. Extension hoppers can be installed at 90° from the original auger to make turns and extend Flex-Flo Augers without using elbows.

Drop Tubes

Drop Tubes

AP’s original drop kit is available for all Flex-Flo Systems providing a totally enclosed outlet drop.

Kwik-Attach Drop Kit

Kwik-Attach Drop Kit

The Kwik-Attach drop kit is easy to install and attaches securely to avoid feed spills. This kit allows for complete clean out of feed and can be adapted with actuators for remote operation.

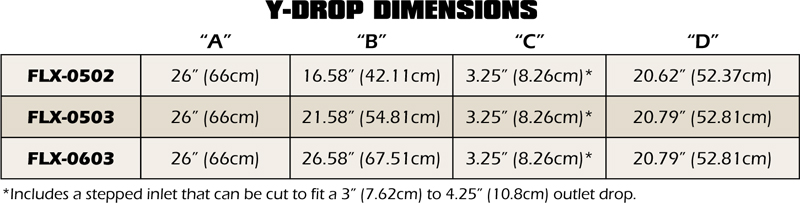

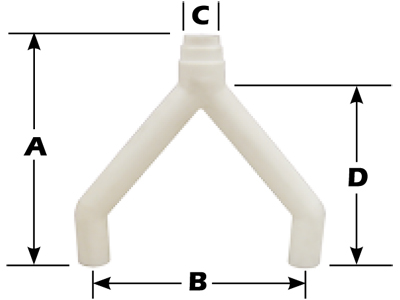

Y-Drop

Chain Disk Feed Delivery

Chain Disk feed delivery systems have the flexibility to adapt to all types of swine production facilities and the ability to overcome the performance and reliability constraints of other systems.

Flexible Design

Flexible Design

Chain Disk is ideally suited to delivering feed to multiple farrowing rooms, individual sow stalls, electronic sow feed systems and the high volume demands of large finishing facilities.

Gentle on Feed

Gentle on Feed

The gentle conveying method limits damage to expensive pelleted rations and prevents particle separation in ground feed rations.

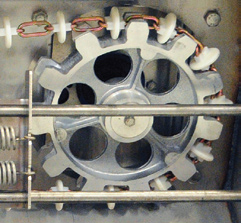

Quality Components

Quality Components

Chain Disk’s rugged design, quality components and unique control system enable it to outperform the competition in capacity, distance and durability.

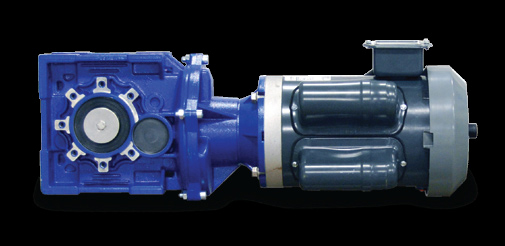

Heavy-Duty Drive Units

Heavy-Duty Drive Units

Chain Disk drive units are constructed of corrosion resistant 304 stainless steel and feature heavy duty, high efficiency, helical bevel gearboxes. High efficiency means more torque with less horsepower decreasing operating cost without sacrificing performance.

Chain Disk drive units feature an automatic chain tensioning system to reduce maintenance and a safety shut off switch to shut down the system if it becomes plugged by a foreign object.

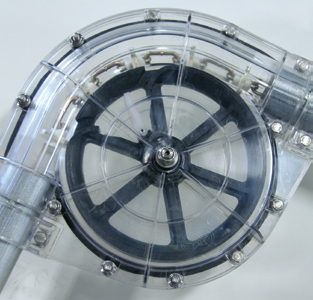

Clear Corner Housings

Clear Corner Housings

Clear corner housings provide visual confirmation the system is operating properly at all times. The patent pending pivoting wiper insures that feed does not accumulate in the center of the corner housing. Special corner units are available for inclined or vertical installation.

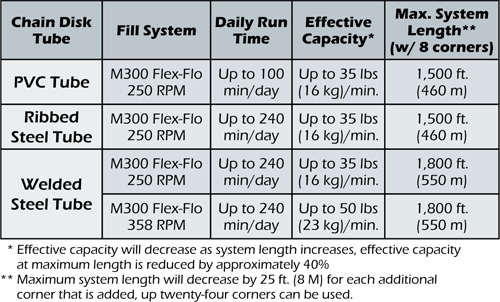

Chain Disk Tubing

Chain Disk is available with three styles of conveyor tubes to meet the requirements of every application.

- PVC Tube – Corrosion free and quick and easy to install, ideal for farrowing and other low volume applications

- Ribbed Steel Tube – Wear resistance of steel combined with the convenience of pre-punched holes

- Welded Steel Tube – Ideal for high volume applications like finishing and electronic sow feeding.

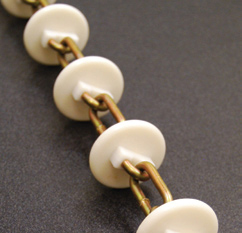

Quality Chain

Quality Chain

Durable, low friction nylon disks injection molded onto hardened steel chain provide years of trouble free service eliminating the maintenance and down time associated with cable style conveyors.

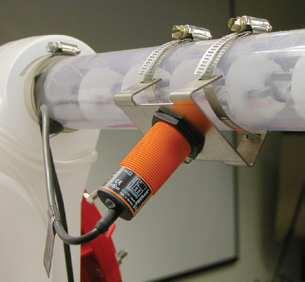

Tube Sensors

Tube Sensors

A tube mounted sensor will shut down the system when feed returns to the inlet hopper indicating that all feeders have been filled. Chain Disk’s sensor design eliminates the challenges caused by empty farrowing or nursery rooms and eliminates the task of correctly position sows in your breeding and gestation facilities to keep the feed system operating correctly.

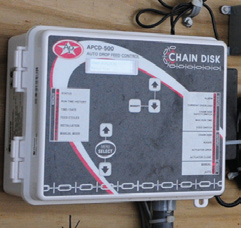

Chain Disk Controller

Chain Disk Controller

The Chain Disk Controller enables the feeding system to be programmed to operate how and when you want and constantly monitors the system to insure proper operation. Drive unit motor current is constantly monitored to insure that the system is not over loaded. When amp draw spikes, the Flex-Flo fill system is temporarily shut down by the controller until the drive unit motor amp draw decreases and normal operation resumes. A programmable maximum run timer will shut down the Chain Disk and the Flex-Flo systems if the system runs continuously for an excessive amount of time indicating that a bin is empty or a costly feed spill is occurring.

Available in two models, the APCD-500 features a 24 hour time clock and actuator outputs making it ideal for automated feeding in breeding and farrowing facilities.

Drop Feeders

AP drop feeders provide you with the tools to maintain individual sow condition, decrease stress during feeding, save labor and prevent feed waste. Our feeders are specifically designed to stand up to the harsh environment, daily use and frequent wash downs encountered in modern sow units. Three models are available allowing you to select the features ideally suited to your facilities and application.

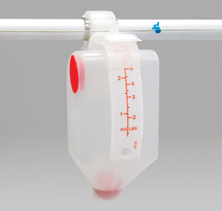

Econo-Drop Feeders

Econo-Drop Feeders

Engineered for reliable performance at an affordable price, AP’s Econo-Drop features a simple front mounted adjustment, individual slide shut-off, and translucent body for visual confirmation of feed level.

Engineered for reliable performance at an affordable price.

Features include:

- Front mounted adjustment.

- Individual slide shut-off.

- Translucent body allows visual confirmation of feed level

- Weighted ball valve securely closes the feeder and insures feed flow when emptying

- All plastic construction with stainless steel hardware

The Econo-Drop feeder is equipped with a conveniently located slide shut-off.

- Econo-Drop’s front mounted adjustment ranges from 1.5 lbs. to 12 lbs. (.68kg to 5.44 kg).

Ultra-Drop Feeders

The Ultra-Drop was designed with producer input to meet the requirements of both gestating and lactating sows. This feeder features convenient one handed

adjustment and a balanced design to insure the feeder hangs straight.

Designed with producer input to meet the requirements of both gestating and lactating sows.

Features include:

Features include:

- Convenient knob adjustment

- Balanced design insures that the feeder hangs straight and maintains accuracy

- Individual slide shut-off.

- Translucent body allows visual confirmation of feed level

- Weighted ball valve securely closes the feeder and insures feed flow when emptying

- All plastic construction with stainless steel hardware

- An easily accessible slide shut-off on the Ultra-Drop cuts feed flow to the feeder.

- A half turn of the convenient adjustment knob adjusts the Ultra-Drop feeder from 1 lb. to 8 lbs. (.45 kg to 3.63 kg).

The Ultra-Drop was designed with producer input to meet the requirements of both gestating and lactating sows. This feeder features convenient one handed

Accu-Drop Feeders

Accu-Drop Feeders

Accu-Drop feeders are designed to fill the highly precise requirements of today’s diverse production systems. The system can be manually operated or fully automated using an actuator system operated by a programmable timer.

Heavy duty construction designed to provide years of durable, reliable performance.

Features include:

- Precision lock-in setting adjustment

- Balanced design insures that the feeder hangs straight and maintains accuracy

- Individual slide shut-off

- Translucent body allows visual confirmation of feed level

- Weighted ball valve securely closes the feeder and insures feed flow when emptying

- All plastic construction with stainless steel hardware

- Cut feed access to the Accu-Drop feeder with a simple rotating shut-off located at the top of the feeder.

- The Accu-Drop adjuster securely locks the feed setting at 1.5 lbs. to 12 lbs. (.68 kg to 5.44 kg).