Commercial Storage Flat Bottom Grain Bins

No one has more experience manufacturing grain storage systems than Westeel. We helped pioneer steel-sided grain storage back in the 1920s and today, as one of North America’s largest producers of grain bins and tanks, we continue to lead the industry in design innovation, quality and product selection. All our products are manufactured under the stringent requirements of ISO 9001, and we employ the latest in computerized design and production technology throughout the manufacturing process. The result is products of superior quality and long-term value – products that represent the finest in on-farm and commercial grain storage available.

For Superior Strength, Structural Integrity and Long-Term Durability, Westeel is the Answer

Choosing the right grain storage system for your operation demands not only a careful analysis of both your short and long term needs, but also an appreciation for the many factors that affect the overall product quality and functionality. At Westeel we pride ourselves on building grain storage products that are considered among the most innovative on the market today. Our new Wide-Corr Centurion series of grain bins and hopper tanks represent the latest in grain storage technology. They employ Westeel’s all-new upright stiffening system, which allows for a more efficient use of steel as well as the ability to maximize bin strength where load stress is greatest. This stiffening system can also be adapted to meet different load requirements of specific installations, as additional stiffening can be added near points of greater load, such as under catwalks. Finally, Centurion series grain bins and hopper tanks offer greater resistance to corrosion and the elements thanks to the use of thicker galvanization on the wall sheets.

Choosing the right grain storage system for your operation demands not only a careful analysis of both your short and long term needs, but also an appreciation for the many factors that affect the overall product quality and functionality. At Westeel we pride ourselves on building grain storage products that are considered among the most innovative on the market today. Our new Wide-Corr Centurion series of grain bins and hopper tanks represent the latest in grain storage technology. They employ Westeel’s all-new upright stiffening system, which allows for a more efficient use of steel as well as the ability to maximize bin strength where load stress is greatest. This stiffening system can also be adapted to meet different load requirements of specific installations, as additional stiffening can be added near points of greater load, such as under catwalks. Finally, Centurion series grain bins and hopper tanks offer greater resistance to corrosion and the elements thanks to the use of thicker galvanization on the wall sheets.

Precision Engineered for Superior Strength

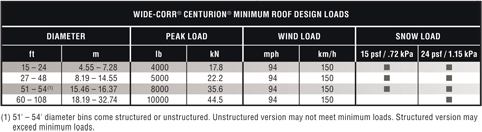

All commercial Wide-Corr Centurion flat bottom bins and hopper tanks are professionally engineered to provide optimum structural integrity from top to bottom. Our engineers have coaxed the maximum strength out of every component used to manufacture a Wide-Corr Centurion bin or hopper. Moreover, every commercial model has been designed to ensure it can withstand the extra stress caused by continuous use, extreme temperatures, high winds and heavy snow loads.

All commercial Wide-Corr Centurion flat bottom bins and hopper tanks are professionally engineered to provide optimum structural integrity from top to bottom. Our engineers have coaxed the maximum strength out of every component used to manufacture a Wide-Corr Centurion bin or hopper. Moreover, every commercial model has been designed to ensure it can withstand the extra stress caused by continuous use, extreme temperatures, high winds and heavy snow loads.

Computerized Manufacturing Process

Westeel employs a computer assisted manufacturing process to ensure precision cut sheets that assemble easily and form snug, weather-tight seals at the connection points. The result is a bin or tank that is easier to erect and provides superior protection for your grain.

Customized Solutions

Highly adaptable to a wide range of applications, Wide-Corr storage systems can be customized to your operation including features such as special discharge outlets, longer hopper legs and reinforced designs for higher catwalk support loads. Regardless of your specialized needs, there’s a Wide-Corr solution available.

Wide-Corr Centurion Storage Bins

Capacities: Storage Up To 674,370 Bushels

Wide-Corr Hopper Tanks

Capacities: Storage Up To 56,570 Bushels

Supper Strong Sidewall Sheets

Centurion sidewall sheets are made from G115 galvanized steel which is 25% heavier than the traditional industry standard G90 and provides a longer coating life for your bin against the elements. Most sheets are rolled from high strength 50-ksi steel and are 44″ tall, which means you use fewer sheets that are lighter but stronger; therefore, fewer seams for improved weather protection. Their ultra flat 4″ corrugation pattern provides superior clean-out without compromising structural strength.

High Strength Bolts

Westeel double bolts (triple on some large diameter bins) all sidewall sheets with high strength Grade 8.2 JS500 zinc plated bolts. Polyethylene washers ensure a weather-tight seal for each bolt.

Heavy Bottom Angle

Heavy Bottom Angle

A heavy bottom angle is used to secure the bin and ensure a positive seal between the sidewall and foundation.

Variable Section Stiffeners (VSS)

Centurion utilizes an all-new upright technology called Variable Section Stiffener (VSS) which works on the principle that the greater the vertical load required, the larger the stiffener section should be. This means the uprights and the section change in thickness from top to bottom. For additional value, our new upright laminating system allows the use of pre-galvanized material and minimizes the use of the splice plates in most connections.

Specially Designed Crawl Door

Factory assembled and installed, Centurion features a standard heavy-duty 24″ diameter crawl door manufactured on a heavy wall sheet for secure fit and easy access.

Stronger, Easier to Install Roof

Stronger, Easier to Install Roof

Westeel’s all-new patented* commercial series roof has been designed for faster assembly and improved overall strength. Manufactured using the latest in computerized automated production equipment, this new roof features fewer parts than the competition and an innovative design making it the fastest and easiest roof to install in the industry. The number of roof vent openings (if required) can be customized and pre-punched during the manufacturing process, meaning that on-site cutting is no longer required. Roof strength has also been improved thanks to 100% bolting on all roof panels and a tight middle connection. For extra insurance against sagging and leaking from heavy loads of snow or ice, heavy beam roof framing supports with patented continuous ring-purlins, and tension plates have also been incorporated.