SeedStor-K™ Hopper Bottom Bins

SeedStor has come to be known for its super fast, controlled unloading capabilities and affordable all-in-one price. SeedStor–K provides the same high quality bin/cone combination as SeedStor with the advantages of a unique knock-down cone design. This design allows the cone to be shipped flat and assembled on site, providing significant savings on transportation costs. And, because the cone is built as an integral part of the bin, assembly will be quicker, more precise and will produce an overall more dependable product.

Exeptional Bin Clean-Out

Unlike some competitive bins which use light internal stiffeners backed by foam, SeedStor–K has no internal stiffeners, thereby eliminating the potential for grain or product hang-up. This in turn reduces the likelihood of fungus growth and insect infestation.

Ideal for Indentity Preserved Seed

Ideal for Indentity Preserved Seed

SeedStor–K incorporates the latest in storage technology, making it perfect for the storage of identity preserved seed and today’s higher density crops such as durum and peas. Because the cone is designed to be an extension of the bin, optimal structural integrity is obtained for the strongest bin/cone combination anywhere.

Designed for Optimal Strength

Engineered for exceptional strength, SeedStor–K has been tested to 50% overload so it can handle any crop without fear of structural failure. It features Hollow Structural Section (HSS) steel construction legs for superior vertical and lateral strength.

Guaranteed to Last

Mounting a bin on an unmatched cone can cause failure of the ring beam, thereby causing structural failure of the bin wall. Because of this, most bin warranties in the industry are voided if a nonmanufacturer approved cone is installed under the bin. With SeedStor–K you have peace of mind knowing both the bin and the cone are made by and warranted by Westeel, even for the storage of peas.

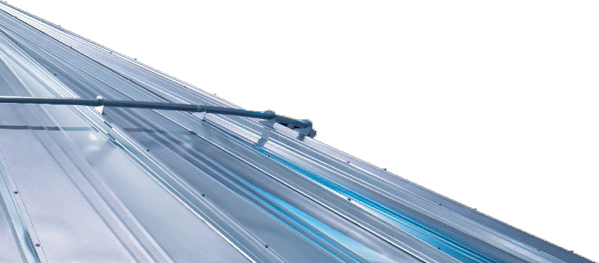

Advanced Roof Design Up To 63% Stronger

Advanced Roof Design Up To 63% Stronger

Westeel’s all-new roof design – the result of years of engineering and real-world testing – provides from 12% to 63% more compressive strength and 25% to 124% greater bend resistance over conventional roof designs. Additionally, the new roof assembles more easily, requires fewer panels and is available with pre-punched vent openings, eliminating the need to cut openings on site. Finally, the wider roof panels make possible a standard 24” inspection hatch on all models.

Standard Equipment

Standard Equipment

- Westeel Wide–Corr® quality bin

- Westeel knock–down hopper design with a 45˚ cone slope for 15 to 21′ models, and a 40˚ cone slope for 24′ and 27′ models

- Galvanized hopper sheets and tubular leg braces

- Powder coated ring beam and legs

- 16″ cone opening

- Remote cap opener

- Roof inspection hatch

- Roof ladder

- Grain Gauge™

SeedStor–K is available in sizes from 2,747 to 7,953 bushels (unstiffened models) and 4,370 to 18,798 bushels (stiffened models).

Heavy duty versions are available in 21′, 24′ and 27′ diameters and should be used with aeration and inspection hatches, or where the unload rate exceeds 2 or 3 cycles per year.