Brock Grain Dryers

FULL HEAT CONTINOUS FLOW DRYERS

SQ D Series Full Heat – Single Zone

CONTINUOUS FLOW DRYERS WITH LOUVERS

SQ E Series

Modified Full Heat – Single Zone or Two Zone

Pressure Heat / Pressure Cool

Pressure Heat / Vacuum Cool

SQ M Series

Modified Full Heat – Single Zone or Two Zone

Pressure Heat / Pressure Cool

CONTINUOUS FLOW DRYERS WITH LOUVERS AND HOT AIR RETURN DUCTS

SQ A Series

Modified Full Heat – Single Zone or Two-Zone

Pressure Heat / Pressure Cool

Pressure Heat / Vacuum Cool

Hot Air Return Ducts

Unique EVENFLO® Unloading System

Unique EVENFLO® Unloading System

Is Part of Brock’s Difference by Design

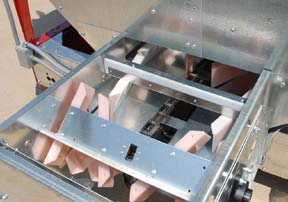

- Gentle handling of the grain using the EVENFLO® System’s efficient, slow-moving drag-style conveyor.

- Patented conveyor unloading system replaces auger and metering rolls.

- Even unloading of grain columns with improved ability to pass most debris.

- More durable and safer to operate than auger systems.

Take-up adjustments are located at both ends of the conveyer. This feature helps you to easily adjust the chain if needed.

Take-up adjustments are located at both ends of the conveyer. This feature helps you to easily adjust the chain if needed.

Take-up adjustments are located at both ends of the conveyer. This feature helps you to easily adjust the chain if needed.

Take-up adjustments are located at both ends of the conveyer. This feature helps you to easily adjust the chain if needed.

How Does the Brock EVENFLO® Dryer Unloading System Work?

- The top portion of the chain conveyor passes by the column of dried grain, continuously removing grain from the column.

- Grain is then carried to square holes allowing the grain to fall through to the bottom trough.

- Paddles on the conveyor move the dried grain to the dryer discharge.

Clean up between crops or at the end of the drying season is easy:

Clean up between crops or at the end of the drying season is easy:

- The top cover of the conveyor assembly can be removed for safer, easier cleaning.

- No meter rolls to clean.

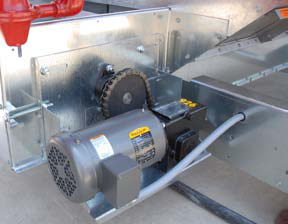

Low horsepower, variable speed AC motor is used to economically power the EVENFLO System.

Low horsepower, variable speed AC motor is used to economically power the EVENFLO System.

Moisture Equalizers

Patented Brock MOISTURE EQUALIZER® System maintains grain quality by moving the hottest and driest grain through the dryer faster for greater drying uniformity and less over-drying.

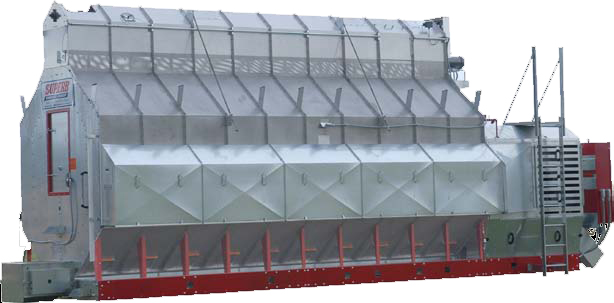

Stainless Steel Outer Skins

Stainless steel outer 18-gauge perforated skins are standard on all SUPERB ENERGY MISER® SQ Series Dryers for a lifetime of satisfaction. With proper care and maintenance, stainless steel perforated skins offer long life and high asset retention value.

Vertical Access Plenum Door

Vertical Access Plenum Door

A 42- x 22-inch (107- x 56-cm) vertical access door is provided for easy access to the dryer’s plenum areas. A door safety switch is standard on all SUPERB ENERGY MISER Low-Profile Dryers. If the door is opened during operation, the dryer will shut down.

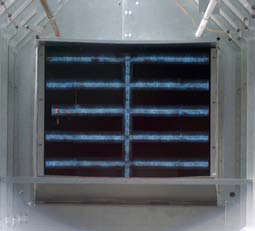

Efficient Full Flame-Wall Burner

Efficient Full Flame-Wall Burner

Brock’s full flame-wall burner with stainless steel baffles provides a generous square footage of flame surface and distributes heat evenly to all the grain columns. Using a shorter flame, this fuel-efficient Brock burner burns cleanly and provides uniform plenum temperatures to help maintain top grain quality.

Unobstructed Heat Movement

Unobstructed Heat Movement

The SQ Series Dryer’s unique built-in vaporizer is located out of the burner’s airflow to ensure uniform heat distribution.

Perforated Wet Garner Bin

Perforated Wet Garner Bin

The drying process starts in the perforated wet garner bin. Heated air is routed from the dryer through this temporary grain holding area to pre-heat and begin drying the wet grain.

Variable Width Grain Column

Variable Width Grain Column

A narrower upper grain column allows moisture saturated drying air to escape. This variable width design dries more effectively than a larger holding capacity with a wider grain column.

Easy Access for Service

Easy Access for Service

Access entrances at both the top and bottom of the dryer make it easy to service industrial grade plumbing, burner, fan, motor, bearings, belts, linear limits, and the front of the unloading system.

Super Quiet Drying

Super Quiet Drying

The SQ Series Dryers use a super quiet double-width, double-inlet centrifugal blower as standard equipment. This blower provides maximum airflow and efficiency while minimizing sound levels.

Cool Air Control

Cool Air Control

Adjustable cooling louvers help control grain temperature by regulating the amount of cool air used for vacuum-cooling mode.

QUANTUM® Controller A Proven Record Of Reliability

Brock’s advanced QUANTUM® Dryer Controller option offers total dryer management through a moisture-based controller popular for farm and commercial use:

- Easy to setup and use to provide accuracy for controlling moisture during the grain drying process.

- Includes a patented “moving moisture target” feature for full-heat drying. In this control mode:

- Control the final moisture of the grain reaching the bin and manage the grain’s moisture content as it moves through the dryer.

- Monitor moisture level fluctuations in incoming and out-going grain as well as outgoing grain temperature changes.

- Regulate the discharge speed of grain to match unloading system capacity.

- Prevent over-drying by automatically reducing plenum heat if the unloading rate limit is exceeded.

- Easy 24/7 remote connectivity using a Web browser and a personal computer, smartphone or tablet to monitor your dryer.

SPECTRUM® Controller

SPECTRUM® Controller

Brock’s SPECTRUM® Dryer Controller is a temperature-based controller and is the standard dryer controller for Brock’s SQ Dryer Series. It is mounted in a lighted, industrial-grade control panel that is weather- and dust-proof and has dual doors.

The SPECTRUM® Controller is also easily upgradable to convert it to the more full-featured QUANTUM® Dryer Controller.